In the modern manufacturing landscape, CNC plastic machining has emerged as a pivotal technology that significantly enhances production efficiency and accuracy. But what exactly is CNC plastic machining, and how does it streamline production? This article delves into its definition, benefits, applications, and cost-effectiveness, while comparing it with traditional manufacturing methods.

Understanding CNC Plastic Machining: An Overview

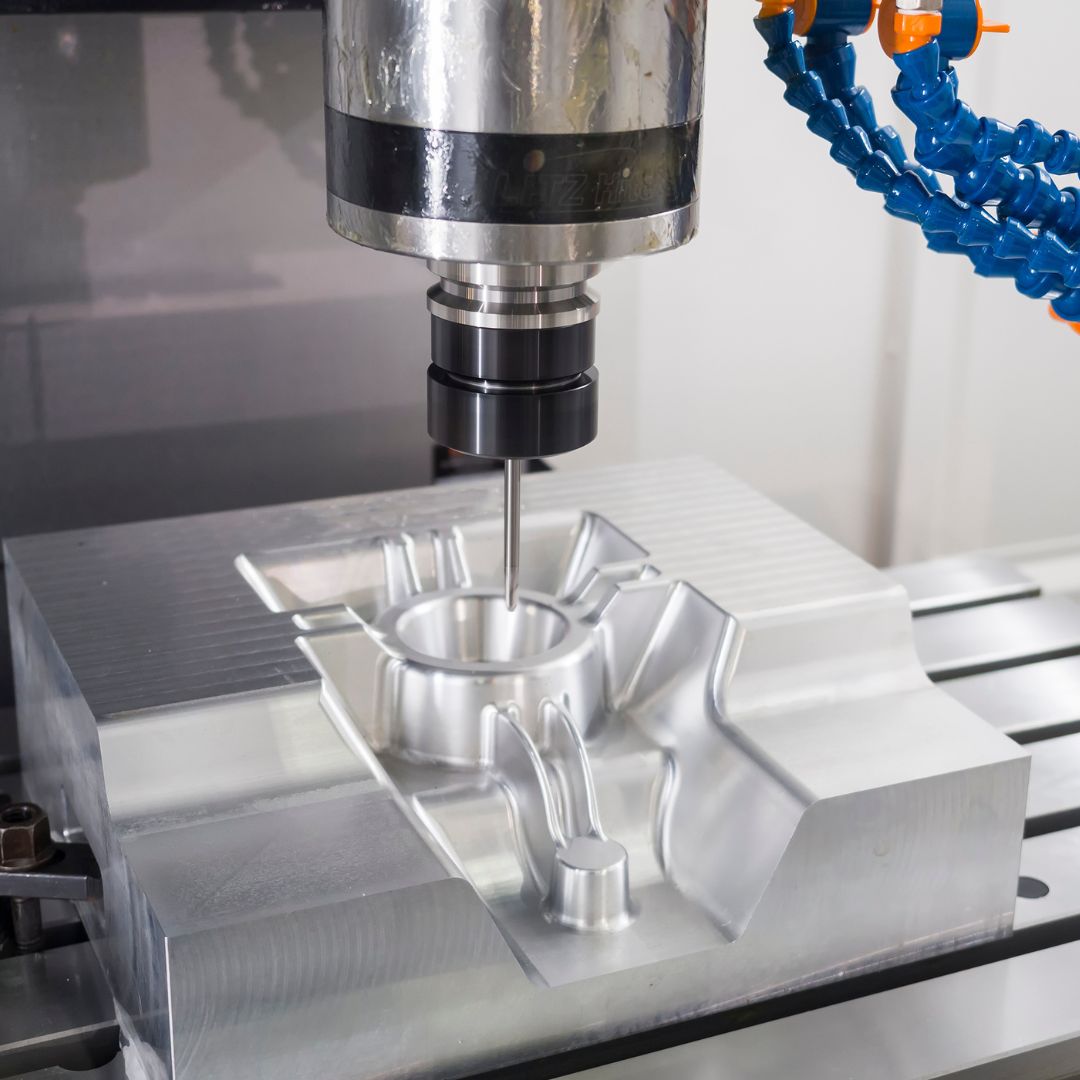

CNC (Computer Numerical Control) plastic machining refers to the process of using computer-controlled machines to cut, shape, and finish plastic materials. This technology allows for high precision and repeatability in the production of complex components, making it indispensable for various industries.

What is CNC Plastic Machining?

CNC plastic machining involves the use of various techniques, including milling, turning, and drilling, to create plastic parts from raw material blocks or sheets. The process begins with a digital design, typically created using CAD (Computer-Aided Design) software. This design is then converted into a format that CNC machines can interpret, allowing for automated manufacturing with minimal human intervention.

Types of Plastics Used in CNC Plastic Machining Services

A variety of plastic materials can be machined using CNC technology, including:

- Acrylic: Known for its clarity and strength, acrylic is often used in displays and signage.

- Polycarbonate: This durable plastic is resistant to impact and is commonly used in safety glasses and protective shields.

- Nylon: With its excellent wear resistance, nylon is favored for gears and bearings.

- PTFE (Teflon): Renowned for its non-stick properties, PTFE is ideal for applications requiring low friction.

Understanding the characteristics of these materials is crucial for selecting the right plastic for specific applications of CNC plastic machining services.

The Benefits in Manufacturing of Plastic CNC Machining Near Me

Plastic CNC machining near me offers numerous advantages that contribute to streamlined production processes.

High Precision and Consistency

One of the primary benefits of CNC plastic machining is its ability to produce parts with high precision. The technology ensures that every component is manufactured to exact specifications, reducing the likelihood of defects and minimizing waste.

Flexibility in Design

CNC machining allows for intricate designs that are often impossible to achieve with traditional manufacturing methods. This flexibility enables manufacturers to customize products according to client specifications, enhancing customer satisfaction.

Rapid Prototyping

CNC plastic machining facilitates rapid prototyping, enabling businesses to create and test designs quickly. This speed is invaluable in industries where time-to-market is critical, allowing companies to stay ahead of competitors.

Reduced Labor Costs

With automated processes, CNC machining reduces the need for manual labor, leading to lower labor costs. Additionally, the technology requires fewer operators, allowing companies to allocate their workforce more efficiently.

How CNC Plastic Machining Enhances Precision and Accuracy

Precision and accuracy are paramount in manufacturing, and CNC plastic machining excels in these areas.

Computer-Controlled Precision

CNC machines are programmed to execute precise cuts and movements. This computer-controlled approach minimizes human error, ensuring that each part is manufactured to the exact dimensions specified in the design.

Advanced Tooling Techniques

CNC plastic machining utilizes advanced tooling techniques that enhance the accuracy of cuts. Tools can be designed specifically for certain materials, optimizing the machining process and improving the finish quality of the parts produced.

Real-Time Monitoring

Many modern CNC machines come equipped with real-time monitoring systems that track the machining process. This feature allows operators to detect potential issues early, ensuring that production remains within tolerance levels.

Key Industries Utilizing CNC Plastic Machining

CNC plastic machining is employed across various industries, each benefiting from its unique capabilities.

Aerospace Industry

The aerospace sector relies on CNC plastic machining for producing lightweight components that meet strict safety standards. The precision of CNC machining is crucial for parts that must endure extreme conditions.

Automotive Industry

In the automotive industry, CNC plastic machining is used for manufacturing interior components, dashboards, and even some exterior parts. The ability to produce complex geometries helps manufacturers create innovative designs that enhance vehicle performance and aesthetics.

Medical Devices

The medical industry frequently utilizes CNC plastic machining to produce components for medical devices. The precision and cleanliness of the machining process are vital for ensuring the safety and efficacy of these products.

| Application Area | Description | Benefits |

| Custom Parts Manufacturing | Production of parts tailored to specific needs or designs. | Flexibility in design, reduced lead times |

| Complex Assemblies | Creation of intricate designs and assemblies that are difficult to fabricate traditionally. | High precision, improved fit and alignment |

| Integration with Other Technologies | Combining CNC plastic machining with 3D printing and robotics for enhanced production. | Streamlined processes, hybrid product capabilities |

| Environmental Considerations | Utilizing recycled plastics and minimizing waste through precise machining processes. | Sustainable practices, reduced environmental impact |

Electronics

CNC plastic machining is also prevalent in the electronics sector, where it is used to create housings, connectors, and other components that require high precision and reliability.

Comparing CNC Plastic Machining to Traditional Methods

When assessing manufacturing options, it is essential to compare CNC plastic machining with traditional methods.

Traditional Machining Methods

Traditional machining methods, such as manual milling and turning, often involve significant human intervention. While these methods can be effective, they are prone to human error and may not achieve the same level of precision as CNC machining.

Speed and Efficiency

CNC plastic machining significantly enhances speed and efficiency compared to traditional methods. Once the design is programmed, the CNC machine can operate continuously, producing parts at a faster rate while maintaining accuracy.

Scalability

CNC plastic machining is highly scalable, allowing manufacturers to easily adjust production volumes. This adaptability is particularly beneficial for businesses experiencing fluctuating demand, as they can quickly ramp up or scale down production without major changes to their processes.

Cost Efficiency: How CNC Plastic Machining Saves Money

Cost efficiency is a critical consideration for any manufacturing operation, and CNC plastic machining can lead to significant savings.

Reduced Material Waste

CNC machining optimizes material usage by cutting parts from larger blocks or sheets with minimal waste. This reduction in waste directly translates to cost savings, making CNC machining a financially viable option for many manufacturers.

Lower Labor Costs

As previously mentioned, the automation of CNC processes reduces the need for manual labor. This reduction in labor costs allows companies to invest more in technology and innovation rather than personnel.

Long-Term Investment

While the initial investment in CNC machinery can be high, the long-term savings in labor and material costs, coupled with increased production efficiency, make CNC plastic machining a sound investment for manufacturers.

Innovative Applications of CNC Plastic Machining

As technology advances, the applications of CNC plastic machining continue to expand, leading to innovative uses across various fields.

Custom Parts Manufacturing

CNC plastic machining allows for the production of custom parts tailored to specific needs. Whether for prototyping or low-volume production runs, this capability enables businesses to offer unique solutions to their clients.

Complex Assemblies

With the ability to create intricate designs, CNC plastic machining can produce complex assemblies that would be challenging to fabricate using traditional methods. This versatility is particularly advantageous in industries requiring precise alignment and fitting of components.

Integration with Other Technologies

CNC plastic machining is increasingly being integrated with other technologies such as 3D printing and robotics. This integration allows for more streamlined production processes and the ability to create hybrid products that leverage the strengths of multiple manufacturing methods.

Environmental Considerations

As sustainability becomes a priority for manufacturers, CNC plastic machining presents opportunities to reduce the environmental impact of production. The precise nature of the machining process leads to less waste, and the ability to use recycled plastics is becoming more prevalent.

In conclusion, CNC plastic machining plays a vital role in modern manufacturing by enhancing precision, efficiency, and cost-effectiveness. As industries continue to evolve, the demand for CNC plastic machining services will likely grow, making it essential for manufacturers to understand and leverage this technology to stay competitive. Whether you are searching for plastic CNC machining near me or looking for reliable CNC plastic machining services, recognizing the benefits of this innovative technology will help you make informed decisions that drive your business forward. For more information, consider reaching out to industry experts or consulting case studies from leading companies in your field.