Are you looking to maximize accuracy with high-temperature thermocouple wires? Whether you’re in an industrial, laboratory, or scientific research setting, the precision of temperature readings significantly impacts processes and outcomes. High-temperature thermocouple wires play a pivotal role in achieving precise temperature measurements in high-temperature environments. Let’s delve into the nuances of high-temperature thermocouple wires, the factors affecting their accuracy, choosing the right type for precision, installation best practices, maintenance, calibration, and troubleshooting common issues.

Understanding High-Temperature Thermocouple Wires

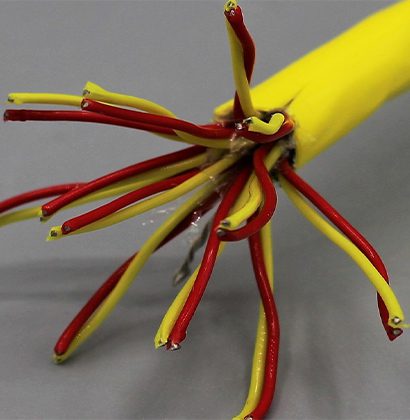

High-temperature thermocouple wires are designed to withstand extreme temperatures, making them suitable for applications where standard thermocouples would fail. These wires consist of two different metal alloys that produce a voltage proportional to the temperature difference between the hot and cold junctions. The ability to function effectively in high-temperature environments is a defining characteristic of these wires, ensuring accurate temperature measurements in challenging conditions.

Composition and Construction of High-Temperature Thermocouple Wires

High-temp thermocouple wire is typically composed of robust metal alloys such as platinum-rhodium, nickel-chromium, or tungsten-rhenium. These alloys are carefully selected for their ability to maintain stability and accuracy in high-temperature environments, ensuring reliable performance in demanding industrial and scientific applications.

Applications of High-Temperature Thermocouple Wires

These specialized calibrated thermocouple wires find extensive use in industries such as aerospace, automotive, manufacturing, and energy production, where processes involve exposure to extreme heat. Additionally, high-temperature thermocouple wires are utilized in research and development settings, particularly in materials science, metallurgy, and high-temperature chemistry experiments.

Factors Affecting Accuracy in Thermocouple Wires

Several factors can influence the accuracy of temperature measurements obtained through thermocouple wires. Understanding and mitigating these factors are crucial for maximizing accuracy and reliability in temperature monitoring.

Material Degradation and Oxidation

High temperatures can lead to material degradation and oxidation, affecting the stability and accuracy of thermocouple wires. This degradation can result in drift, where the thermocouple’s output changes over time, leading to erroneous temperature readings.

Thermal EMF Variation

Variation in thermal electromotive force (EMF) across the length of the thermocouple wires can impact accuracy. This variation can occur due to temperature gradients along the wire, leading to measurement errors, especially in high-temperature applications.

Environmental Interference

External factors such as electromagnetic interference, radiation, and chemical exposure can introduce inaccuracies in temperature measurements obtained through thermocouple wires. Shielding and proper installation practices are essential for minimizing environmental interference.

Choosing the Right Type of Thermocouple Wire for Precision

Selecting the appropriate type of thermocouple wire is pivotal for achieving precision in temperature measurements, especially in high-temperature environments. Each type of thermocouple wire has distinct characteristics that make it suitable for specific applications.

| Platinum-Rhodium vs. Nickel-Chromium Thermocouple Wires |

| Platinum-rhodium thermocouple wires are renowned for their exceptional stability and accuracy at high temperatures, making them ideal for demanding applications in industries such as aerospace and metallurgy. On the other hand, nickel-chromium thermocouple wires offer good performance at lower costs, catering to a wide range of industrial temperature measurement needs. |

Consideration of Temperature Range and Environmental Conditions

When selecting thermocouple wires, it is imperative to consider the temperature range of the application and the environmental conditions to which the wires will be exposed. Choosing the right type of thermocouple wire based on these parameters is essential for maximizing accuracy and longevity.

Calibration and Traceability

Opting for calibrated thermocouple wires with traceable certification ensures that the wires meet specified accuracy standards. Calibration enhances the accuracy of temperature measurements and provides assurance of consistent performance.

| Characteristics | Platinum-Rhodium Thermocouple Wires | Nickel-Chromium Thermocouple Wires |

| Stability and Accuracy | Exceptional stability and accuracy at high temperatures | Good performance at lower costs |

| Applications | Demanding applications in aerospace and metallurgy | Wide range of industrial temperature measurement needs |

| Temperature Range Suitability | Suited for high-temperature environments | Suited for moderate to high-temperature applications |

| Cost | Higher cost | Lower cost |

Installation Best Practices for Maximizing Accuracy

Proper installation of high-temperature thermocouple wires is fundamental for ensuring accurate and reliable temperature measurements. Adhering to best practices during installation mitigates potential sources of error and contributes to the longevity of the thermocouple system.

Minimizing Thermocouple Wire Stress

Avoiding excessive tension or bending of thermocouple wires during installation is crucial for preventing mechanical stress that could lead to inaccuracies in temperature readings. Employing gentle handling and appropriate support mechanisms minimizes the risk of wire damage and maintains accuracy.

Ensuring Proper Grounding and Shielding

Effective grounding and shielding techniques are essential for minimizing electromagnetic interference and external noise that can compromise the accuracy of temperature measurements. Proper grounding practices dissipate electrical noise, while shielding protects the thermocouple wires from external influences.

Location and Placement Considerations

Careful consideration of the installation location and placement of thermocouple wires is vital for accurate temperature monitoring. Placing the thermocouple junction in close proximity to the area of interest and away from heat sources or potential sources of interference optimizes the accuracy of temperature measurements.

Regular Inspection and Maintenance

Implementing a schedule for regular inspection and maintenance of the thermocouple system ensures early detection of potential issues and contributes to sustained accuracy. Periodic checks for physical damage, oxidation, and environmental effects are essential for maximizing the lifespan and reliability of the thermocouple wires.

Maintaining and Calibrating High-Temperature Thermocouple Wires

Maintaining the accuracy and reliability of high-temperature thermocouple wires involves regular calibration and diligent upkeep. Calibration procedures and proactive maintenance practices are integral to preserving the precision of temperature measurements.

Importance of Regular Calibration

Regular calibration of thermocouple wires is indispensable for verifying their accuracy and correcting any deviations in output. Calibration procedures involve comparing the thermocouple’s readings with a reference standard to ensure consistent and precise temperature measurements.

Traceability and Standards Compliance

Calibrating high-temperature thermocouple wires in accordance with recognized standards and maintaining traceability to national or international measurement standards is essential for upholding accuracy and quality assurance. Adhering to established calibration protocols instills confidence in the reliability of temperature measurements.

Proactive Maintenance Strategies

Proactive maintenance encompasses periodic inspection, cleaning, and assessment of the thermocouple system to identify and address potential issues that could compromise accuracy. Regular maintenance routines contribute to prolonged operational integrity and optimal performance of thermocouple wires.

Troubleshooting Common Issues with Thermocouple Wires

Despite meticulous care and adherence to best practices, thermocouple wires may encounter issues that affect their accuracy. Understanding common problems and their resolutions is imperative for maintaining the precision of temperature measurements.

Drift and Inaccuracy

Drift, characterized by gradual changes in the output of thermocouple wires over time, can lead to inaccuracies in temperature readings. Recalibration and assessment of the thermocouple system are necessary to rectify drift and restore accuracy.

Mechanical Damage and Degradation

Mechanical damage or degradation of thermocouple wires due to excessive bending, abrasion, or exposure to harsh conditions can compromise their performance. Replacement of damaged wires and implementation of preventive measures are essential for mitigating the impact of mechanical damage.

Environmental Influences

Environmental factors such as chemical exposure, radiation, or extreme temperatures can impact the accuracy of thermocouple wires. Evaluating the environmental conditions and implementing protective measures or alternative materials can mitigate the effects of external influences.

In conclusion, high-temperature thermocouple wires are indispensable for achieving accurate and reliable temperature measurements in high-temperature environments. Understanding the nuances of these specialized wires, mitigating factors affecting accuracy, selecting the right type, adhering to installation best practices, conducting regular maintenance and calibration, and addressing common issues are pivotal for maximizing accuracy and precision in temperature monitoring applications. By implementing these strategies, industries, laboratories, and research facilities can optimize their temperature measurement processes and enhance operational efficiency.