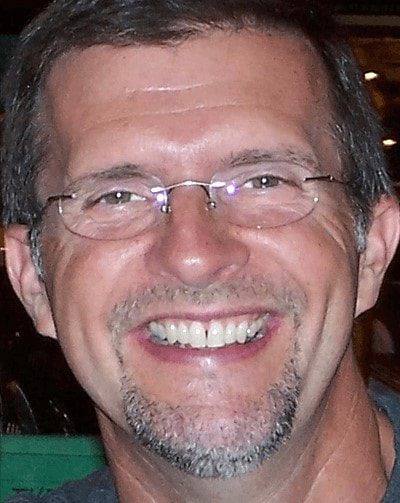

Greg Stout is a freelance rotational molding designer who specializes in rotational molding design, blow molding design, thermoforming / vacuum forming design, and injection molding design. His company Blue Reed was set up for just that and Stout and his team can guide you through each step of the design process while creating a high quality and great looking product. On top of that, Blue Reed will work with its clients to help find the best materials through product manufactures or help clients meet certain specifications for their designs. What other designer can say that?

Rotomolding design is a specialized field that has a unique set of rules and regulations to ensure that a product can be successfully rotationally molded and achieve all the required specifications. It not only takes experience with the rotational molding process, knowledge of the rotational molding companies who will be manufacturing the product as well as materials, tooling, material flow in addition to a strong plastics engineering background to successfully design rotomolded products. It’s a narrow field but Greg Stout has all the knowledge and skill that you will ever need in a plastics designer. He fits all the criteria and more with Blue Reed. He has fit all the criteria for over 25 years to be exact. And he will work with you to ensure that the manufacturers give you good prices without skipping out on the quality product that you are looking for. Rotational molding and hollow plastic product design are what Blue Reed specializes in and if you are looking for more information on what Stout and Blue Reed can do for you or if you have any questions as to what rotational molding is or the guidelines, click on the link above or call Blue Reed at 330-322-8707.

Rotational molding can be dated back to 1855 as a process used to create a metal product, actually. The Sun Rubber Company is credited for starting it. They were producing rubber balls and hot water bottles before using plastic to create hollow doll heads in 1955. Rotational molding continues to change and grow over the years. Perhaps the greatest advantage of rotational molding is that you are able to incorporate many parts into one. This saves time and cost. The greatest disadvantage is that there are not a lot of resin options to choose from. However, the advantages far outweigh the disadvantages. Contact Greg Stout and Blue Reed, LLC, to find out what he can do for you today and advise you more on what is rotational molding and to see if it would fit your design best.