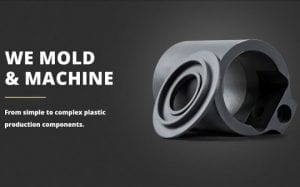

Since 1948, Jaco Molding Products, an injection molding company in Ohio, has offered custom injection molding of thermoplastic materials up to 29 oz. Their reputation for injection mold technology has established Jaco Products as experts and leaders in production and precision plastic injection molding services and they also offer parts at a competitive price within the industry. They also serve as the largest supplier of plastic machining and stamping.

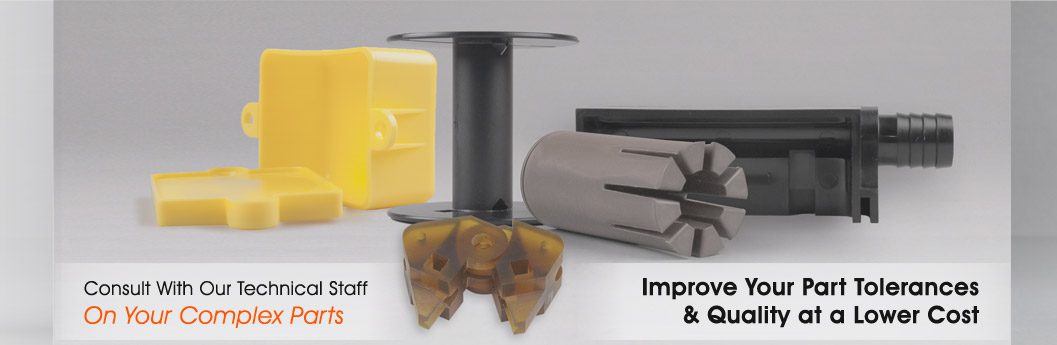

As one of the premier injection molding companies in Ohio, Jaco has a highly trained staff of technicians and engineers who know every step and aspect of the injection mold process and will do the job with precision and professionalism. Since a wide array of materials are available for the process, including polypropylene, polystyrene, polyethylene, PVC, etc, their technical staff can go over-application of your injection molded parts to determine what will be the best-designed component for the injection molding process. Each step will be well thought out and expertly executed. Their many services include post-mold machining, ultrasonic welding, and assembly. They can also assist with material recommendations, product design and prototype molding manufacturing. From their extensive state-of-the-art equipment, including in-house facilities for tool design and CAM and CAD computer programs to aid in manufacturing, to their knowledge of resin systems, a number of mold cavities, and process requirements Jaco is able to identify the lowest cost method to manufacture your plastic product. By trusting Jaco Molding Company you are trusting in their modern equipment, precision to detail and highly trained engineers to get the job done right by creating a finished product that will produce the best results possible.

In 1948, Jaco Molding Products, a plastic injection molding company in Ohio, was started and their reputation as experts in the field has only grown since then. Jaco offers custom injection molding of thermoplastic materials up to 29 oz and while being leaders in production and precision plastic injection molding services, they also offer parts at a competitive price within the industry. Jaco Molding Products also serves as the largest supplier of plastic machining and stamping and they also offer many different services including, thermoplastic injection molding, prototype molding, and CNC machining.

As one of the premier plastic injection molding companies in Ohio, Jaco has a highly trained staff of technicians and engineers who know every step and aspect of the injection mold process and will do the job with precision and professionalism. Since a wide array of materials are available for the process, including polypropylene, polystyrene, polyethylene, PVC, etc, their technical staff can go over-application of your injection molded parts to determine what will be the best-designed component for the injection molding process. Each step will be well thought out and expertly executed. They can also assist with material recommendations and product design. From their extensive state-of-the-art equipment, including in-house facilities for tool design which are designed by local mold builders, to their knowledge of resin systems, a number of mold cavities, and process requirements Jaco is able to identify the lowest cost method to manufacture your plastic product. The company follows the Society of Plastic Industry (SPI) industry practice that regards maintenance and mold ownership for custom injections. By trusting Jaco Molding Company you are trusting in their modern equipment, precision to detail and highly trained engineers to get the job done right by creating a finished product that will produce the best results possible.

Jaco Products is the Best Plastic Machining Manufacture in Ohio.